for Timber Treatment Plant Operators

Preservative treatment plant operators need very specific information to assist them in the operation of the plant and the marketing of their products.

Koppers Performance Chemicals technical representatives are available in each state and territory to assist with any day to day issues of plant operation and the Koppers Performance Chemicals head office can assist with market level enquiries, including operation of standards and building codes.

If you need further information please contact us and we will endeavour to provide the information you need.

SDS (Safety Data Sheets for our Antisapstain)

Safety Data Sheets are provided to plant operators, simply click the button below to access this information as pdf's. Please note that these are NOT SDS's for the treated timber product.

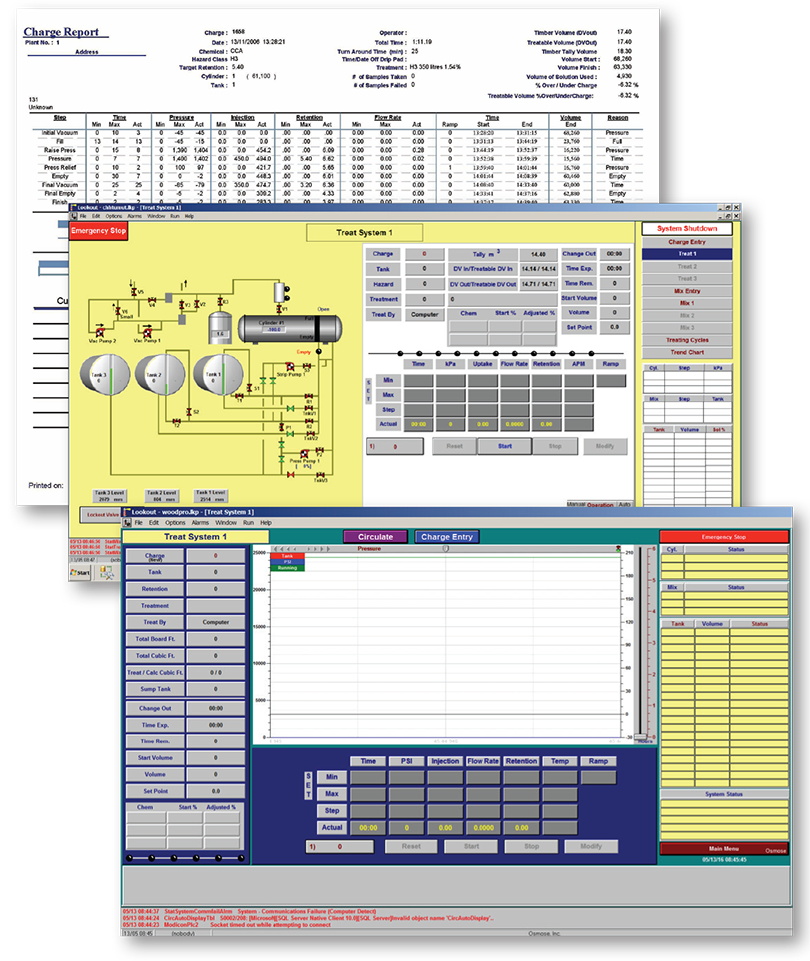

Process Control System

Have greater control over your operation!

Designed and developed by Koppers engineers, the Koppers Process Control System (PCS) has been designed to meet the requirements of customers who demand the highest level of process control and information management.

- Better manage your treatment costs

- Produce management reports

- Interface with your accounting system

PCS Key Features

- The Koppers PCS can be fully customised to suit your unique operation

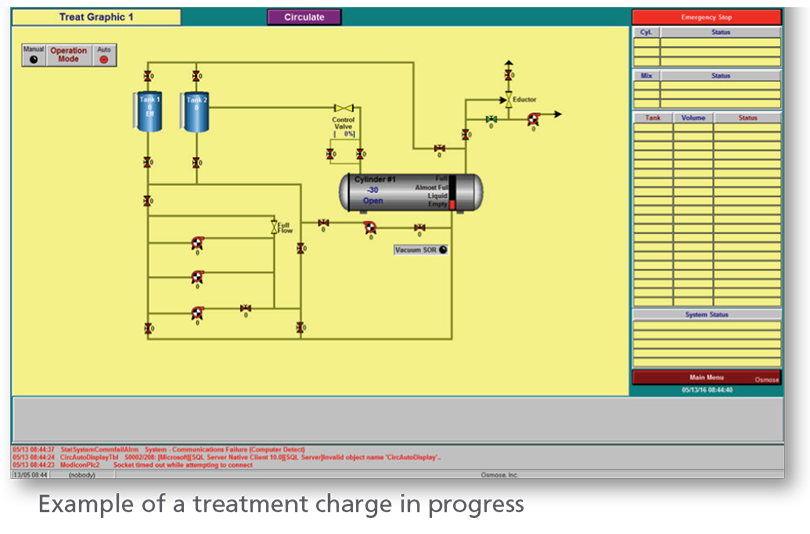

- Full automation or manual override

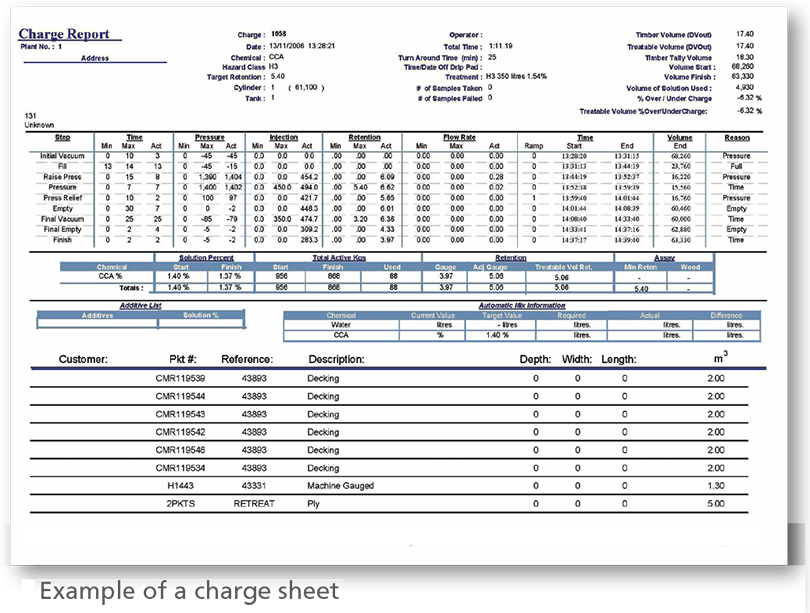

- Detailed charge by charge information including reconciliations

- Detailed process information

- Interface with inventory control and accounting systems

- Security and access protocols

- PCS can manage up to three treating cylinders simultaneously

- Phone support and remote log-in

- Flexible system allows new formulations and or process cycles to be added or modified at any time

- Automated backup system

- Data search function

Additional Benefits

- High Quality Components ...

are used to automate your treatment plant. - Two PC’s ...

are used in a network, in case one PC fails the other one can continue to run your plant. - Uninterrupted Power Supply (UPS) and surge protection ...

is always installed to minimise interruption. - User friendly ...

and easy to learn interface. - Safety system ...

logs all plant actions and alarms. - Emergency notification ...

with telephone or paging system. - Automatic top up mix system ...

calculates chemical additions - then controls the additions with a single button click. - Tank circulation can be automated ... can be left running as it will pause when the tank is in use for treating.

- Allows easier troubleshooting of hardware problems.

Training and Ongoing Support

On-site training will be supplied by your Koppers® Territory Manager. Back-up and support is just a phone call away as most questions should be able to be dealt with over the phone. Our representatives are also able to provide on-site assistance during our service calls.

Koppers Performance Chemicals conducts a number of Plant Operator Training courses. If you are interested in attending please contact us for detailed training information.